Design

Fabmaker

The 3D-Printer for Education

one

The Challenge

When i was working at this StartUp, we wanted to make a 3D Printer that is easy to use, safe and reliable. Most of the cheaper 3D Printers lack this attributes. You always have to tweak a bit and repair a lot or the prints are failing very often.

two

Concept

We came up with an enclosure, so that the students won't burn their fingers. The Door can be locked with a key, which is given to the teacher. With the big Glassdoor makes it is still possible to follow the printing process. An Easy to use touchscreeninterface is located on the right side of the door, to controll the printing parameters.

three

Solutions

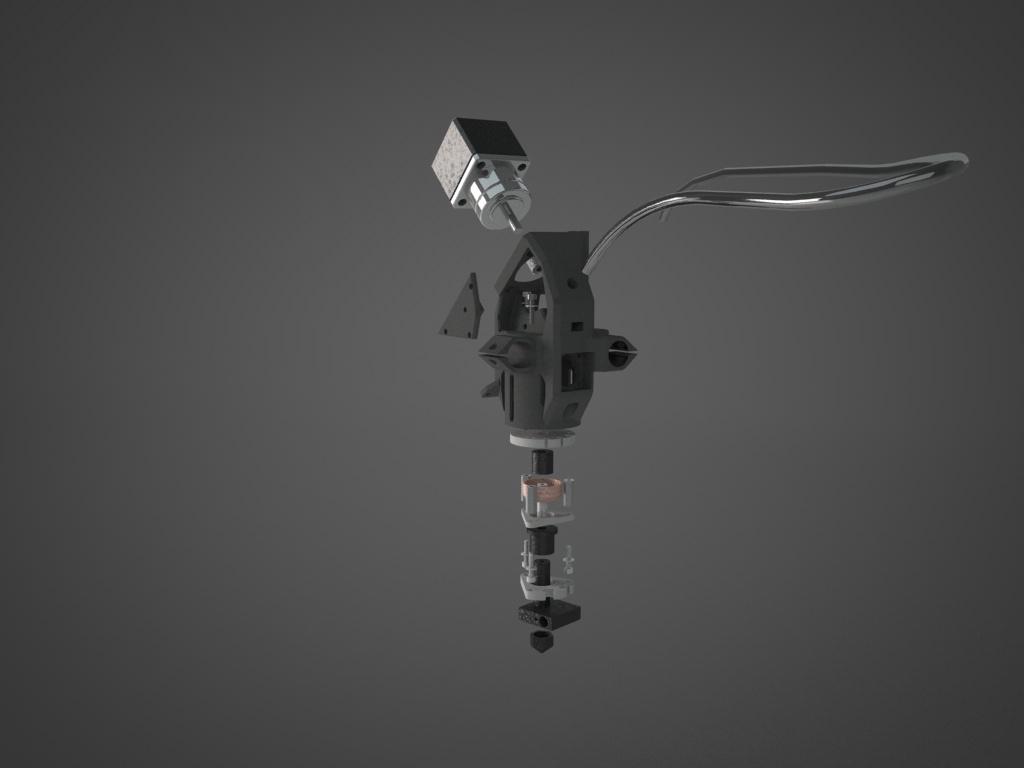

We did a lot of iterations to find the perfect X,Y-drive and developed a lightweight extruder head, which was intended to be 3D printed as well. We invented a quick-exchange system to switch easily between different nozzles. Easy maintenance was also one of our focus points

four

Details

The Filamentspool is also mounted inside the case to keep it dry and safe. The fumes are cleaned through two carbonfilter underneath the ventilators on top. Some other concepts thought of a drawer on the bottom of the printer, multicolor extrusion, automated nozzle exchange, and many more features.

Summary

A Failure

Fabmaker – The 3D Printer for Education

2013

Sadly, the two Founders seperated their paths and most of us left the company. Today, the printer is available, but with another design and a lot of different approaches. It was a great experience to work at a StartUp and feel the spirit in the team.

I did a lot of mechanical engineering, designed the housing for the interface and created the renderings and animations